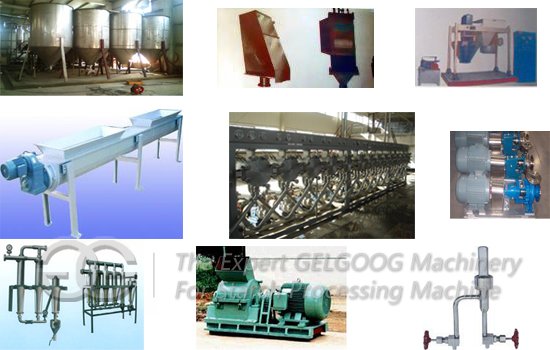

Corn Starch Production Line

you have many size to choice including Yield Specifications: hourly 200Kg, 500Kg, 1000Kg, 1500-2000Kg, 5000Kg, 10000KG

Application

Main Feature

Features

NOTE:

We also have other capacity for your choice such as 1000kg per hour

If you need corn starch production line equipment quotation or have any other machine problems please leave messages on our website we will reply you as soon as possible or you can chat online with our customer service.

Technical Data

| Model | name |

Quantity (set) |

Power (kw/set) |

Materials (T/h) |

material | note | |

|

Soak corn |

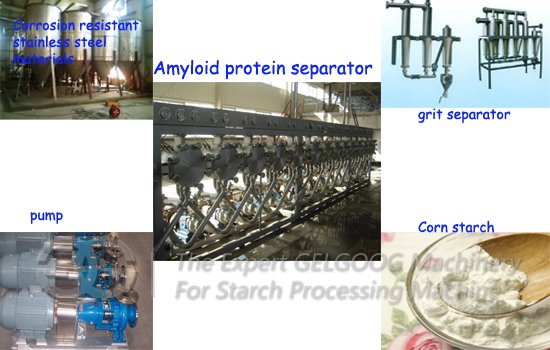

Soak pot material | 50m2 | Corrosion resistant stainless steel materials |

On-site technical guidance production; Corn soaking jar, acid tower. 3000 * 3000 * 6000 |

The material purchasing, local equipment to provide technical drawings, the buyer is responsible for the production. |

||

|

Soak sulfurous acid from corn |

1 |

5Cubic meters |

corrosion-resistant material |

Acid filling, furnace, stainless steel pump, etc |

The material purchasing, local equipment to provide technical drawings, the buyer is responsible for the production. |

||

| Soaked corn processing section | |||||||

| GGSF—1 | Water curved screen | 1 | 1 | Stainless steel |

Supplies water separation device 780*650*1400 |

||

| GGZW--330 |

degerming mill |

1 | 7.5 | 300KG |

General material |

After soaking maize embryo off; 1600*650*800 |

|

|

Germ body separation section |

|||||||

| GGPF—1.0 |

Germ floating tank |

1 | 1 | 300KG | Stainless steel |

Germ body separator; 1200*1200*1200 |

|

| GGFR—1 | Points milk curved screen | 1 | 300KG | Stainless steel |

Endosperm slurry separation device; 780*650*1400 |

||

| GGZW—330Ⅱ | fine grinder | 2 | 7.5 | 100KG | General |

Secondary fine crushing body; 1600*650*800 |

|

|

After fine grinding slag slurry separation washing section |

|||||||

| GGXD--60 | Washing sieve | 3 | 3 | 300KG |

Contact material is stainless steel |

Sieve bravery, stainless steel screen mesh supporting each one; Separation of starch washing fibers; 1600*1400*1650*5 |

|

|

Separation and purification of starch section |

|||||||

| GGXL—170 | Amyloid protein separator | 1set | 3*7 | 150KG |

Separating the protein in washing refined starch, fine fiber impurities such as: 7500*2000*1400 |

||

| Refined starch dehydration section | |||||||

| GGSS-1000 |

dehydrator |

1 | 7.5 | 100KG |

Contact material is stainless steel |

Dehydrated water -- to wet starch 40%. 5800*2800*3000 |

|

| GGWL—200 | Feeder | 1 | 3 | 100KG |

Contact material is stainless steel |

To the conveying of the |

|

| Drying product starch section | |||||||

| GGFG—150 | dryer | 1 | 11 | 100 |

Pipe is stainless steel |

Drying starch used to 13% moisture. 10m*6m*14m |

|

| GGCP—600 | Final Screen | 1 | 0.75 | 100 | galvanize |

Sieve the impurity in the finished product starch and grain fineness of 100 mesh. 3500*1500*2500. |

|

|

The conveying material process pump |

|||||||

|

stock pump |

4 | 2 | 5 |

Conveying material in serum 650*450*450 |

|||

|

stock pump |

1 | 2 | 5 |

Delivery of corn; 650*450*450 |

|||

| acid proof pump | 1 | 3 | 5 |

Sulfurous acid water use; 750*650*850 |

|||

| Product packaging starch | |||||||

|

Packing scale (portable sewing machine) |

1 | 0.1 | Weighing starch and sealing. | ||||

| Equipment control cabinet | 4 |

Workshop equipment control panel |

|||||

|

grit separator |

2 |

Workshop equipment control panel 1600*259*259 |

FAQ

Yes, but your side will pay the engineer salary and the air ticket and the visa.

2. What's the material of the machine?

The contact food part is staninless steel.

3. What's the starch extraction rate?

Generally can arrive to 95%.