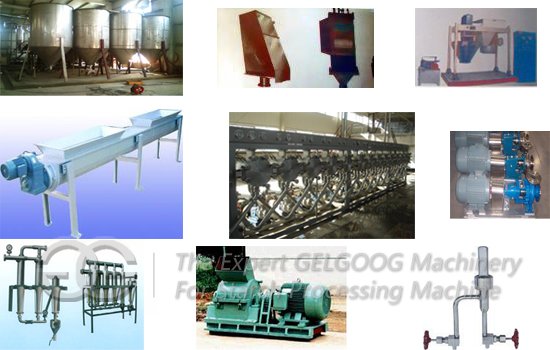

1000kg/h Corn Starch Production Equipment

1. using the most advanced and mature technology 2.integrated structure, CIP online cleaning system 3. lower operating costs 4.The control system is easy to operate, reliable

Application

Main Feature

Features

1 ton starch erengy consumption:

Technical Data

| Model | Name |

Quantity (set) |

Power(kw/set) | (T/h) | Materials |

remark |

| GG--00 | Corn soaking jar | 6 | 30-40m³/piece | 6 |

preservative Carbon steel |

Steel, channel steel, Angle steel, anticorrosive material, flange, valve, etc. Homemade system to the scene |

| System of acid tank | 1 | 30m³ | Stainless steel |

Steel, channel steel, Angle steel, anticorrosive material, flange, valve, etc. Homemade system to the scene |

||

| noncorrosive pump | 2 | 5.5 | ||||

| Corn pump | 4 | 7.5 | ||||

| GG-100 | Water curved screen |

1 |

3 | Stainless steel | ||

| GG-60 | degerming mill | 2 | 18.5 | 2.5 | Carbon steel | two stage embryo |

| GG-250 | Germ separator | 2sets | 3 | Stainless steel | ||

| GG-1000 | Points milk curved screen | 1 | 3 | Stainless steel | ||

| GG-60 | fine grinding | 1 | 30 | 6-7 | Carbon steel | |

| Embryo spiral flow pump | 2 | 3 |

The lift is 60-80meters |

|||

| GG-710 | Pressure curved sieve | 8 | 20m³ | Stainless steel |

Washing 5-6 times, can Minimize starch content in slag pulp |

|

| GG-60 | Pump for transport Slag pulp | 10sets | 7.5、11 | 30-15 | Stainless st | |

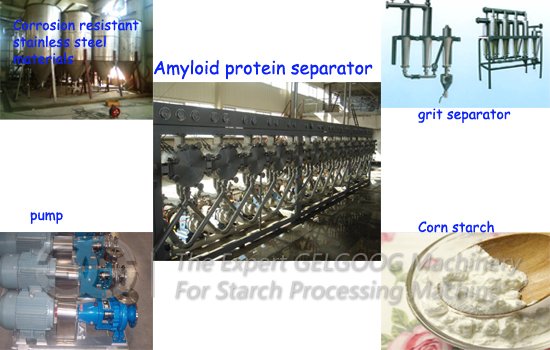

| GG-445 | starch separator | 1 | 30 | 1 |

The part which contact the material is stainless steel |

|

| GG-270 | Desander group | 4 | 30m³ | Stainless steel | ||

| GG-285 |

whirlcone |

12 | 7.5/11 | 20 | Stainless steel |

Pump and slurry pipe are contacted to bracket, and it have the desander, flow meter |

| GG-60-11 |

water pump |

4 | 7-5-.5.5 | 15-30 | Stainless steel |

They are used to deal with Acid water , pipe transition, swirl washing |

| High pot | 1 | 1.1 | Stainless steel | With stirring | ||

| GG-800 | Starch dehydrator | 1 | 30KW | 1 | Stainless steel | |

| GG-650 |

conveyor for Wet material after dehydration |

1 | 4 | 1 | Stainless steel |

Groove width is 650mm with small storage bin |

| GG-1.5 | Starch dryers | 1 | 60+4 | 1.5 | Stainless steel |

It include Fan, drying tube, discharge feeder, feeder, so the heat exchange system, dust removal system, thermometer, insulation materials, |

| GG-100 | finished screen | 1 | 3 | 1.5 | ||

| GG-5 | cooling conveyor system | 1 | 15 | 1.5 | Stainless steel | With stainless steel silo which is 2 cubic |

| workshop equipment control system | 8 groups | |||||

| Flow meter | 1 | 15-30 cubic | ||||

| agitator | 4 | 1.1KW | ||||

| Bleaching equipment | 1 |

Irrigation, furnace, stainless steel pipe |

FAQ

Of course.

2. What's the material of the machine?

The food contact part is stainless steel.

3. Will I match a boiler for this line?

Yes. Suggest you buy it in your coutry.a